Velux is a high end Danish manufacturing company that primarily specialise in producing windows. They pride themselves in providing some of the best quality products in perfect condition every time. As a result, Velux had previously invested heavily into manual quality assurance of their supply chain, to make sure their customers received highest possible quality products with minimal errors.

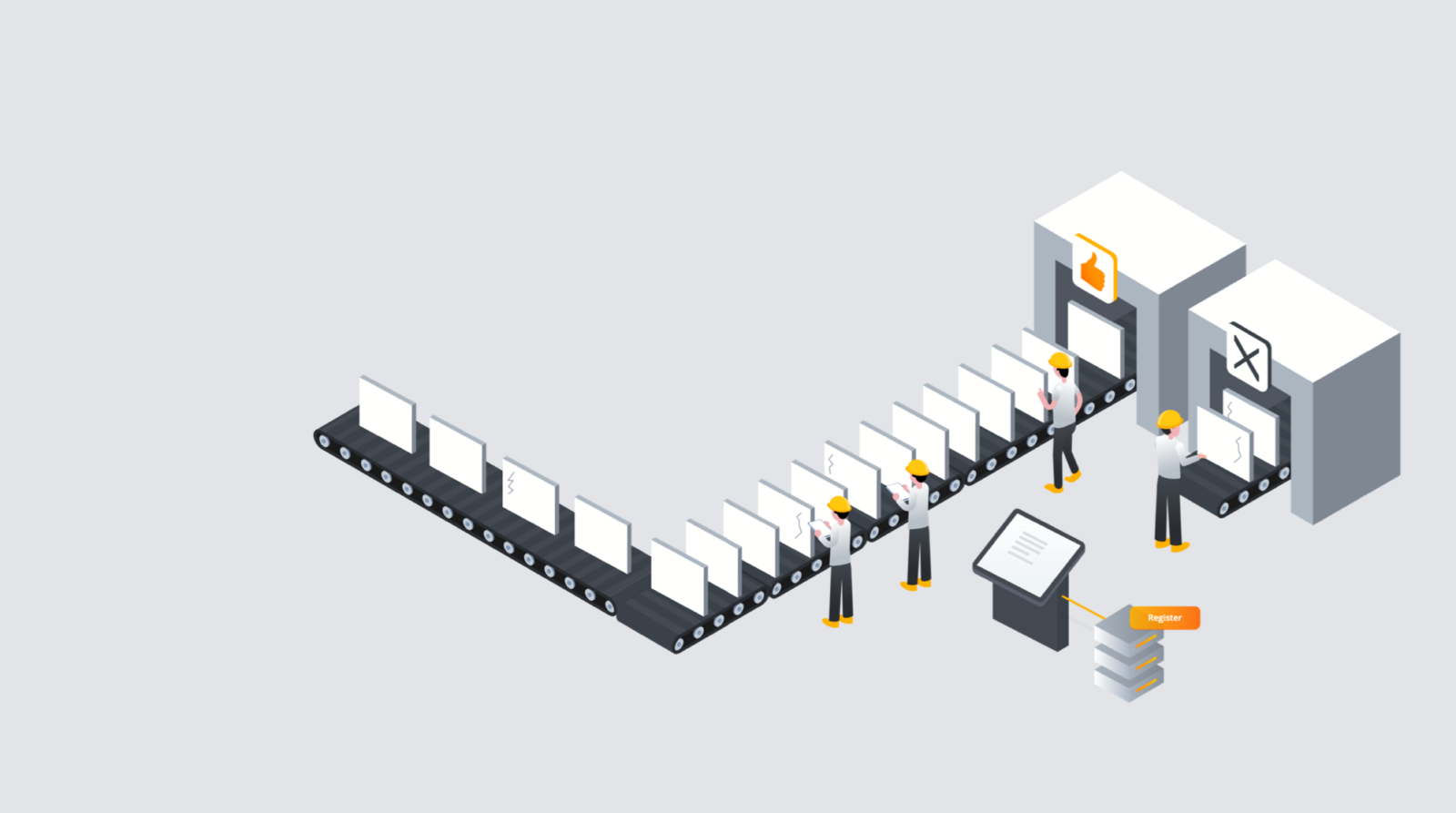

The costs associated with manual quality assurance and error handling in the supply chain were substantial. Velux’s goal was therefore to find a smarter alternative that would reduce the cost of the quality assurance process, while still maintaining the same high-quality standard. Velux needed an automated solution that was unaffected by human errors.

As a change agent, Trifork stepped in to assist Velux on their strategic journey into Industry 4.0.

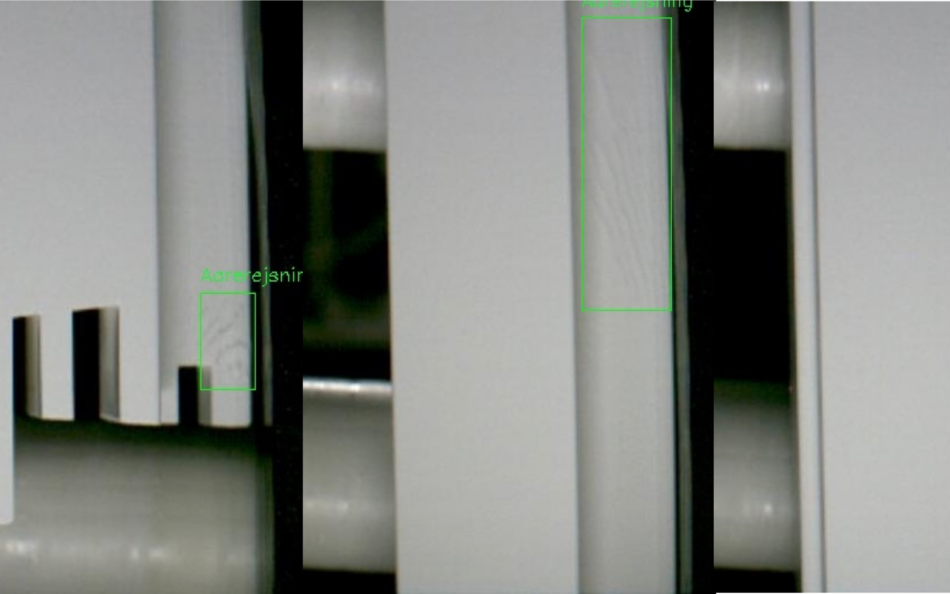

Initially, the objective was to create a Proof in Production (PiP), of which the challenge was to figure out how to identify errors in wooden material. The wood used to produce the windows typically vary in color and structure, which makes it difficult to hard code rules for identification.

Therefore, Machine Learning was an ideal use case for this, as we could train the machine to recognize errors while allowing some abnormalities in the wooden components.

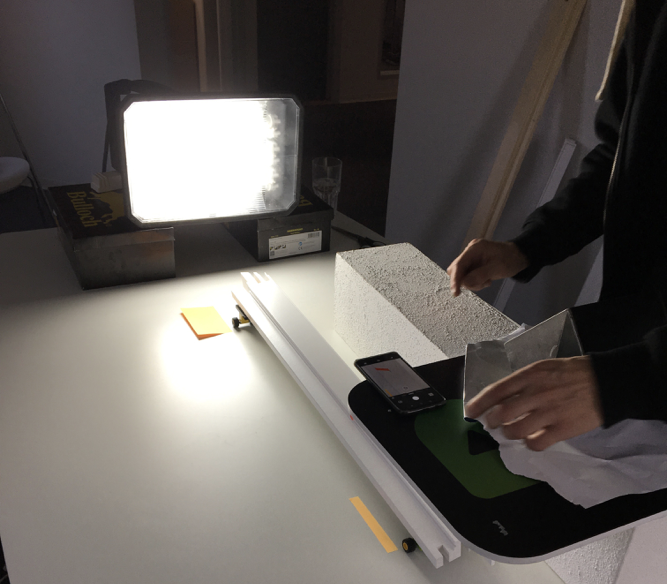

This was initially done by recreating a part of the assembly line, using a few components and pictures from an iPhone. This swiftly showed promising results and the test was quickly able to recognize different types of errors in the materials as well as identify positives (meaning if the material did not have any faults, the machine would not find any).

The value of this solution was immediately apparent – Velux would no longer have to subject to human errors in quality assurance. After the proof in production was validated, the project was quickly escalated to be implemented as part of Velux’s production line.

The solution is now saving Velux a substantial amount of hours in manual labor, avoiding numerous faulty products making it through to the next step in production, the assembling of the final window, and the costs of replacing the component in the final window.

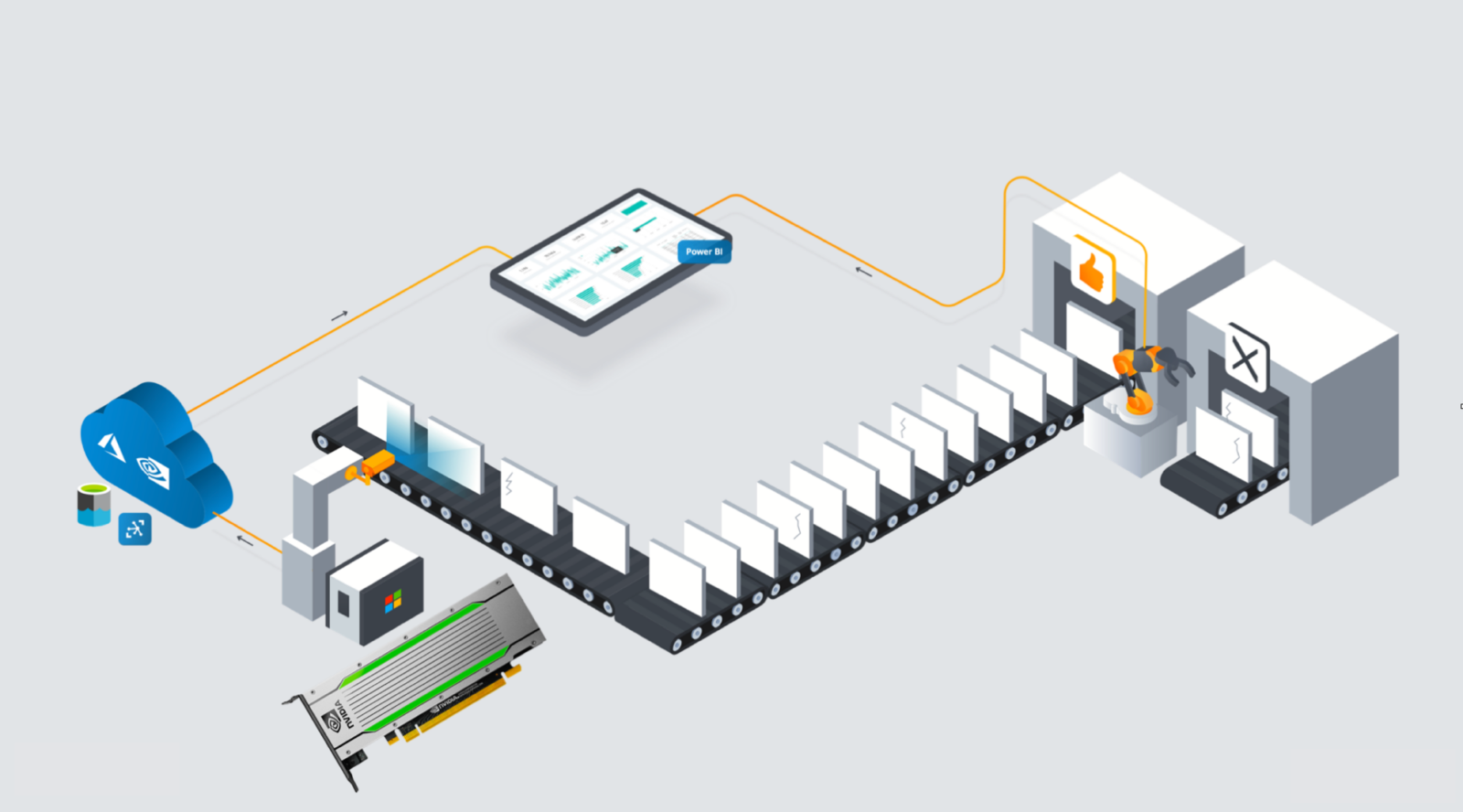

The solution is currently able to analyse 4×80 pictures per second, as it analyses from every angle. In comparison, the human eye can blink five times in a second, meaning that this solution can identify errors 40 times faster than the human eye is capable of blinking.

The machine learning market, especially within production, is currently experiencing massive growth. Trifork’s role is this project has been significant in gaining experience within a field that will affect multiple industries significantly for years to come.

250K

4×80

40x

Trifork always strives to be part of the latest trends in technology. As a result, we often embark on greenfield projects to push the limits of our capabilities. The Velux machine learning project was no different.

For this project, Trifork used the Google Coral USB stack accelerator just four weeks after it launched, and in tandem, used the Azure Stack Edge databox as the fourth company in the world to do so.

To train the machine and to identify & label the wooden components, the Google AI Platform labeling service was used, while Nvida’s Tesla T4 GPU was brought in to power the solution. Finally, Azure IoT Hub allowed cloud support of the solution, while Google AutoML and Nivida Deepstream was used to recognize the images as well as train the machine.

Content