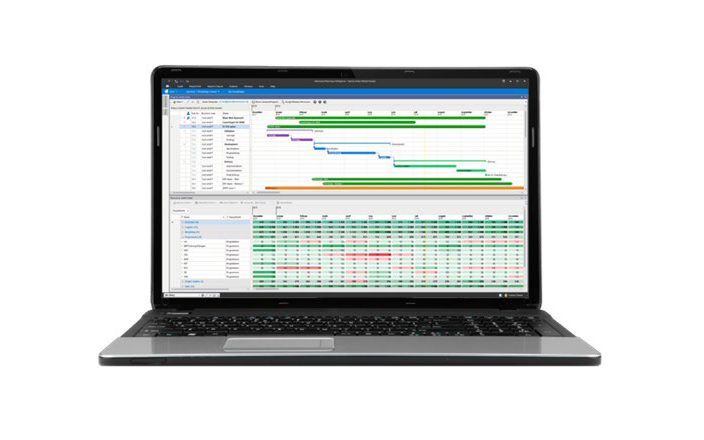

“We have many planning systems in different excel spreadsheets without links, and without a consolidated overview. If We can have our Engineering planning synchronized and constantly updated in one consolidated system with a clear overview, then our efficiency and speed will improve, and our ability to prioritize correct will also improve.”

Content